Optical coatings are crucial in industries like aerospace, automotive, and consumer electronics. They improve optical performance, reduce glare, and protect components. However, traditional methods like sputtering and evaporation face challenges in uniformity and durability.

Atomic Layer Deposition (ALD) overcomes these issues, offering precise control over film thickness and composition. In this article, we will explore how ALD enhances the durability and uniformity of optical coatings, making them ideal for a range of applications.

Key Takeaways

ALD provides precise control over coating thickness: With atomic precision, ALD ensures uniformity across complex surfaces.

Improved durability: ALD coatings offer enhanced resistance to wear, corrosion, and harsh environmental factors.

Ideal for 3D geometries: ALD can conformally coat even the most intricate and high-aspect-ratio surfaces, including lenses and mirrors.

Superior performance in optical applications: ALD coatings, such as AR coatings, improve light transmission, reduce glare, and enhance durability.

Challenges and considerations: While ALD offers excellent uniformity, its slower deposition rate and higher costs may limit its scalability in some applications.

The Science Behind ALD in Optical Coatings

What is Atomic Layer Deposition (ALD)?

Atomic Layer Deposition (ALD) is a chemical vapor deposition (CVD) process that allows for the creation of ultra-thin films, one atomic layer at a time. The process is self-limiting, meaning that each layer is deposited with high precision and uniformity. In an ALD cycle, two reactive gases (precursors) are introduced to the surface of a substrate, reacting with the surface to form a monolayer of material. After each reaction step, the excess precursor and reaction byproducts are purged, leaving behind a highly controlled atomic layer.

This unique process ensures that each layer is deposited evenly, allowing for precise control over the thickness of the coating. With this atomic-level precision, ALD enables the deposition of films that are uniform, pinhole-free, and highly conformal, making it ideal for optical coatings.

ALD vs. Traditional Coating Techniques

| Feature | ALD | Traditional Methods (Sputtering, Evaporation, IBS) |

| Coating Precision | Atomic-level precision | Limited by line-of-sight deposition |

| Uniformity | Excellent uniformity, even on complex surfaces | Non-uniform thickness, especially on 3D surfaces |

| Film Quality | Pinhole-free, smooth films | Prone to defects like pinholes and surface irregularities |

| Deposition Rate | Slower deposition rate | Faster deposition rate but less control over uniformity |

| Material Flexibility | Wide range of materials (oxides, metals) | Limited material compatibility based on deposition method |

ALD's Role in Optical Coatings

ALD plays a critical role in producing optical coatings with excellent uniformity and durability. For optical components such as lenses, mirrors, and filters, ALD ensures that the coatings are not only thin but also highly conformal. The ability to coat intricate geometries without sacrificing film quality makes ALD an ideal technique for high-performance optical applications.

By using ALD for optical coatings, manufacturers can achieve coatings that are pinhole-free, smooth, and uniform, which are essential for maintaining the optical properties of the components. This is particularly important for antireflective (AR) coatings, which need to have a uniform thickness to effectively reduce reflection and enhance transmission.

ALD's Impact on Durability of Optical Coatings

Long-Lasting Performance of ALD Coatings

One of the major advantages of ALD coatings is their superior durability. ALD creates dense, defect-free films with low internal stress, which makes the coatings resistant to wear, corrosion, and environmental degradation. These films can withstand harsh conditions such as exposure to UV radiation, temperature fluctuations, and moisture, ensuring that optical components maintain their performance over time.

For example, in the aerospace industry, optical components must perform reliably under extreme conditions. ALD coatings provide a long-lasting solution by protecting sensitive optical elements from damage caused by environmental factors, ensuring that they continue to function optimally even in challenging environments.

ALD for Harsh Environments

| Environmental Factor | Impact on Optical Coatings | How ALD Helps |

| UV Radiation | Causes degradation and discoloration | ALD coatings provide UV protection, preventing optical degradation. |

| Temperature Fluctuations | Leads to expansion and cracking | ALD coatings remain stable across a wide range of temperatures, offering superior thermal resistance. |

| Moisture Exposure | Can cause corrosion or film delamination | ALD creates dense, moisture-resistant coatings that enhance durability. |

Materials Enhanced by ALD for Durability

Materials like silica (SiO2), alumina (Al2O3), and titanium dioxide (TiO2) are commonly used in ALD to enhance the durability of optical coatings. These materials offer excellent resistance to environmental factors like corrosion and wear. ALD’s precision in depositing these materials allows for the creation of multilayer coatings that can withstand harsh environmental conditions while maintaining their optical properties.

In applications requiring coatings that protect optical components from moisture, UV radiation, or chemical exposure, ALD provides an effective solution. The ability to fine-tune the material composition and layer thickness ensures that the coatings deliver optimal performance in demanding environments.

ALD's Contribution to Uniformity in Optical Coatings

Achieving Even Coatings on Complex Geometries

ALD’s ability to coat complex, high-aspect-ratio surfaces uniformly is one of its key advantages. Traditional coating techniques struggle to achieve even coatings on curved or irregular surfaces, often resulting in thickness variations or shadowing effects. ALD, however, ensures that coatings are deposited uniformly across the entire surface, even on components with complex geometries like domes or aspherical lenses.

| Geometries | Challenges with Traditional Methods | How ALD Addresses Challenges |

| Curved Surfaces | Uneven coatings, shadowing effects | ALD ensures uniform coatings on complex, curved surfaces. |

| High-Aspect-Ratio Structures | Difficulty achieving uniformity | ALD deposits conformal coatings, even on high-aspect-ratio surfaces. |

Minimizing Pinhole Defects with ALD

Pinhole defects in coatings can lead to decreased optical performance, as light can pass through these imperfections, reducing the effectiveness of the coating. ALD’s atomic precision minimizes the occurrence of pinholes, ensuring that the coating is dense and uniform. This is particularly important for optical coatings that must maintain high-quality performance, such as antireflective (AR) coatings used in high-precision optical systems.

ALD’s ability to create smooth, defect-free films makes it an ideal choice for high-performance coatings in sensitive applications where even minor defects can significantly affect the optical properties.

High Reproducibility and Quality Control

ALD is known for its high reproducibility, ensuring that each coating produced is consistent and meets strict quality control standards. This is essential for manufacturing high-quality optical components, where uniformity and precision are paramount. ALD systems are capable of producing coatings with minimal variation in thickness, even across large substrates or complex surfaces.

For manufacturers, this means that they can rely on ALD to produce large batches of optical components with consistent performance, reducing the need for time-consuming rework and ensuring that each component meets the desired specifications.

Practical Applications of ALD in Optical Coatings

ALD in Anti-Reflective Coatings (AR Coatings)

Anti-reflective (AR) coatings are essential in optical systems, as they reduce light reflection and enhance transmission. ALD enables the creation of highly uniform AR coatings with precise control over thickness, ensuring that the coatings perform optimally across a wide range of wavelengths. The ability to fine-tune the thickness of each layer in the AR coating ensures that the desired spectral response is achieved, improving the efficiency of optical systems.

For example, in consumer electronics, ALD AR coatings improve the performance of displays, enhancing clarity and reducing glare. These coatings also provide protection against scratches and environmental wear.

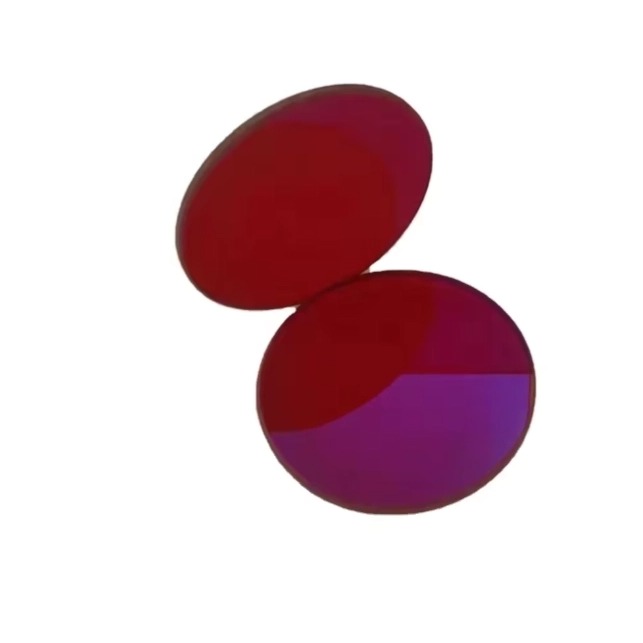

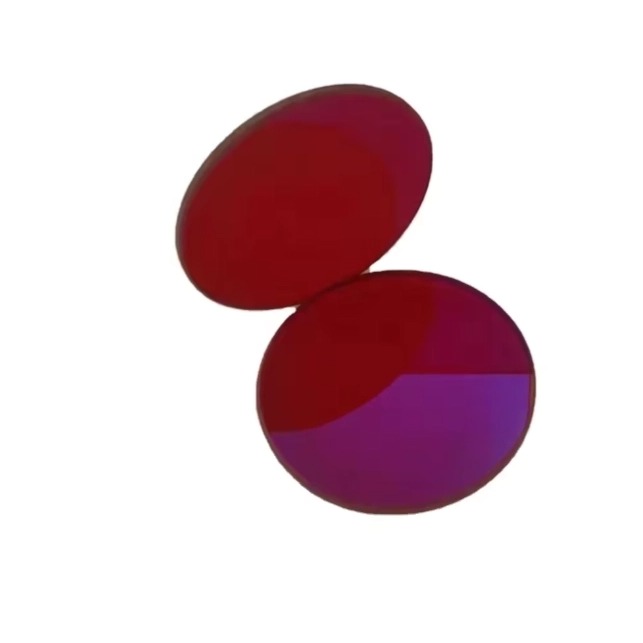

ALD for Specialized Optical Filters

ALD is also used to create optical filters, such as bandpass filters and dichroic filters. These filters are used in a variety of applications, from imaging systems to telecommunications. ALD’s precision allows for the deposition of multiple layers with varying refractive indices, enabling the creation of filters with specific optical properties.

For instance, in optical communication systems, ALD coatings help create filters that selectively transmit certain wavelengths of light, improving signal clarity and reducing interference.

ALD in the Development of High-Performance Lenses

In the development of high-performance lenses, ALD coatings ensure that the lenses maintain their optical properties over time. ALD provides uniform coatings on complex lens geometries, such as large telescope domes, ensuring that the lenses deliver optimal performance. The ability to apply uniform coatings on both the front and back of the lens without affecting its curvature or performance is a significant advantage of ALD.

Challenges in ALD for Optical Coatings

Slow Deposition Rates and Their Impact

One of the main challenges of ALD is its relatively slow deposition rate compared to traditional methods. While ALD offers exceptional precision, its slower processing speed can pose challenges in high-volume manufacturing environments. This can increase production costs and limit the scalability of ALD in some applications.

Cost Considerations of ALD Coatings

Although ALD offers superior coating performance, the high capital costs of ALD equipment and the operational costs of materials and energy can be a barrier for some manufacturers. However, as ALD technology advances and becomes more widely adopted, costs are expected to decrease, making it a more viable option for high-volume production.

Material Compatibility and Process Optimization

The selection of appropriate materials and optimization of the ALD process are crucial for achieving the desired coating properties. ALD coatings must be carefully tailored to suit the specific optical requirements of each application. Additionally, process parameters such as temperature, precursor chemistry, and deposition cycles must be optimized to ensure that the coatings are uniform and durable.

Conclusion

In conclusion, ALD offers significant advantages in the durability and uniformity of optical coatings, making it an ideal choice for high-performance optical components. By providing precise control over film thickness and composition, ALD ensures that coatings are uniform, pinhole-free, and durable, even under harsh environmental conditions. As ALD technology continues to evolve, its impact on the optical coatings industry will grow, offering new opportunities for innovation and performance enhancements.

TAIYU OPTICAL GLASS is a leader in providing high-quality optical glass coatings. Their custom thin optical coatings, designed for space applications, offer superior durability and performance, showcasing the value of ALD in advanced optical systems.

FAQ

Q: What are optical coatings and why are they important?

A: Optical coatings are thin layers applied to optical surfaces to improve performance, such as reducing reflection or enhancing light transmission. They are essential for improving the functionality and longevity of optical components in industries like aerospace, automotive, and consumer electronics.

Q: How does ALD improve optical coatings?

A: ALD enhances optical coatings by providing precise control over thickness and ensuring uniform, pinhole-free coatings. This results in durable and high-quality coatings, even on complex geometries, making ALD ideal for high-performance optical components.

Q: Why is ALD better than traditional coating methods for optical coatings?

A: Unlike traditional methods, ALD ensures uniform deposition on complex surfaces, such as curved lenses, by building up coatings atom by atom. This precision reduces defects and increases durability, making it suitable for high-performance optical applications.

Q: Can ALD be used for anti-reflective coatings in optical applications?

A: Yes, ALD is widely used for anti-reflective coatings in optical applications. It allows for the creation of uniform, high-performance AR coatings, reducing glare and improving light transmission across a wide range of wavelengths.

Q: What materials are commonly used in ALD for optical coatings?

A: Common materials for ALD optical coatings include SiO2, TiO2, and Al2O3. These materials provide excellent optical properties, such as high refractive index and durability, essential for coatings in optical lenses and filters.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori