Infrared (IR) coatings are revolutionizing military and aerospace technologies. These coatings enhance the performance of optical systems by controlling infrared light interactions. In critical applications, such as night vision or thermal imaging, IR coatings improve visibility, reduce heat signatures, and ensure system durability.

In this article, we will explore how IR coatings contribute to military operations and aerospace missions. You will learn about their various applications, from stealth technology to spacecraft thermal control, and understand the innovations shaping their future.

Key Takeaways

Enhanced Performance: IR coatings improve the performance of thermal imaging, night vision, and stealth technologies by allowing or reflecting infrared light in specific wavelengths.

Military Applications: Key uses include thermal imaging systems, night vision goggles, stealth coatings for aircraft, and laser protection in defense systems.

Aerospace Applications: IR coatings are essential for reducing glare, managing heat, and improving sensor performance in satellites, spacecraft, and aircraft.

Advancements in Technology: Future trends in IR coatings include nano-structured and multi-layer coatings that offer improved durability, efficiency, and thermal management.

Challenges and Solutions: The development of more cost-effective and durable materials will be crucial for overcoming environmental and operational challenges in these sectors.

Fundamentals of Infrared Coatings

Types of IR Coatings

| Type of Coating | Function | Application Examples |

| Reflective Coatings | Reflect infrared radiation to reduce heat buildup | Military stealth aircraft, spacecraft insulation |

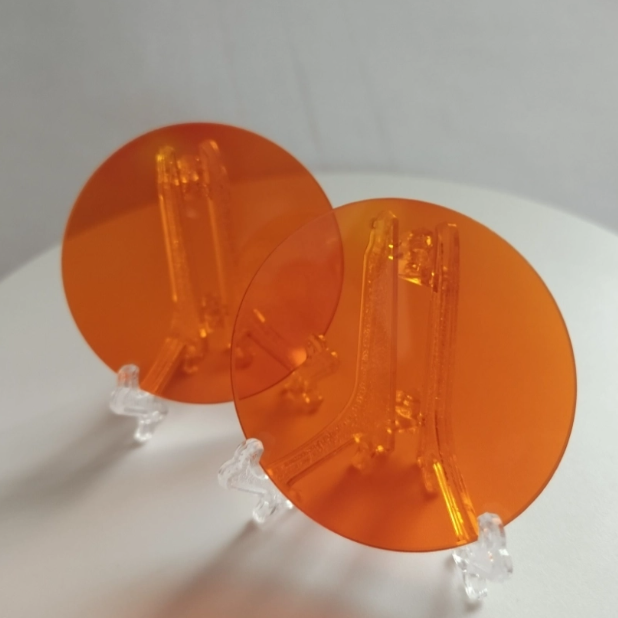

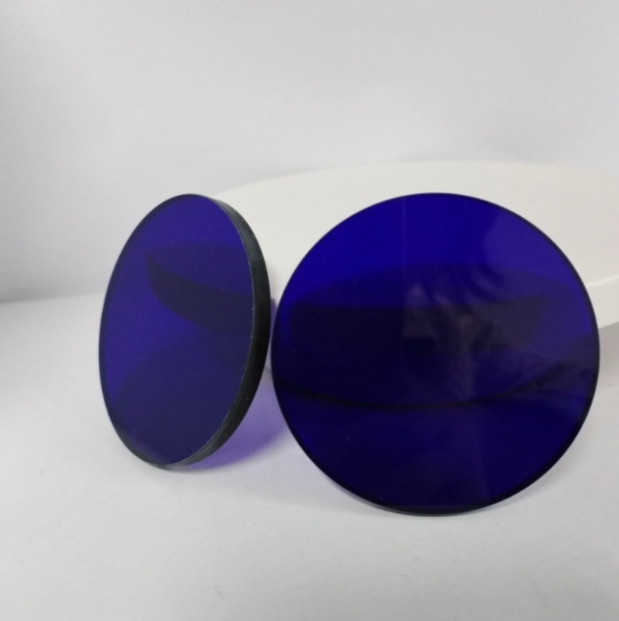

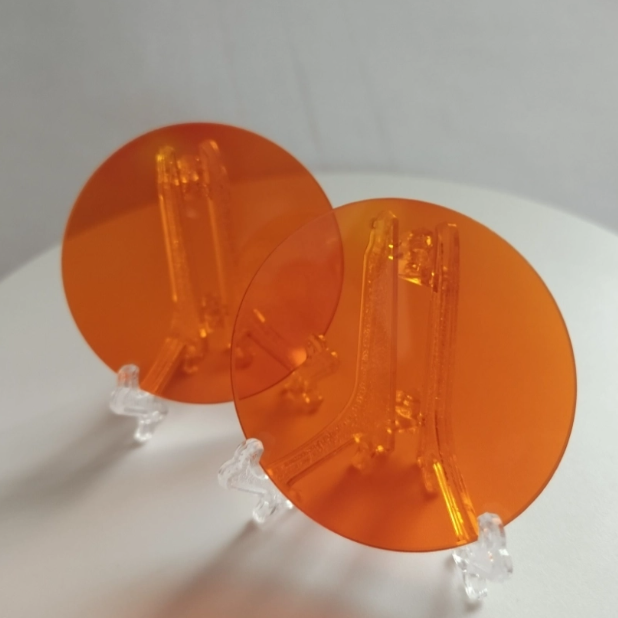

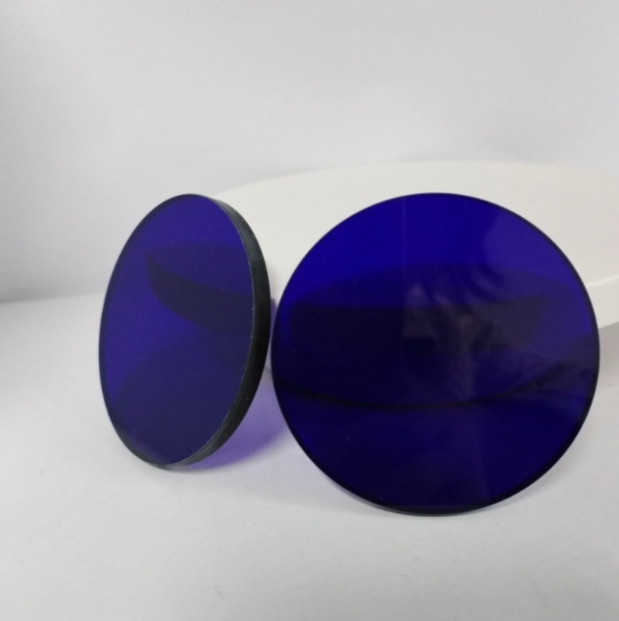

| Transmissive Coatings | Allow infrared light to pass through without interference from visible light | Night vision goggles, thermal cameras, satellite sensors |

Mechanisms of Action

| Coating Type | Mechanism | Application Impact |

| Reflective Coatings | Reflect infrared radiation to control heat | Used in stealth technology to reduce heat signature |

| Transmissive Coatings | Transmit infrared light for imaging systems | Improves clarity in night vision and thermal imaging devices |

Manufacturing and Material Selection

| Material | Application | Properties of Interest |

| Germanium | Used in transmissive coatings | High transparency in infrared, durable |

| Sapphire | Spacecraft sensors | Resistant to high temperatures, strong mechanical properties |

| Zinc Selenide | Thermal cameras, satellite sensors | High infrared transparency, low optical distortion |

Military Applications of Infrared Coatings

Thermal Imaging and Night Vision Systems

Infrared coatings enhance the performance of thermal imaging systems and night vision goggles. These devices rely on IR coatings to provide clear images in low-light or nighttime conditions. By allowing infrared light to pass through optical lenses without distortion, these coatings ensure high-quality thermal images of the battlefield, improving situational awareness.

Stealth Technology and Heat Signature Management

Infrared reflective coatings are widely used in stealth technology. Military aircraft, ships, and vehicles are coated with these materials to reduce their infrared signature, making them harder to detect by enemy sensors. The coatings work by reflecting infrared radiation away from the vehicle, significantly reducing its visibility to thermal imaging and IR-guided missiles.

Case Study: The B-2 Spirit stealth bomber uses sophisticated infrared reflective coatings to reduce its radar cross-section and heat signature, enabling it to remain undetected during missions.

Laser Protection and Countermeasures

Infrared coatings are also essential in military systems for laser protection. These coatings are applied to optical components, including targeting systems and defense lasers, to prevent damage from high-powered laser beams. By absorbing or reflecting harmful laser radiation, the coatings ensure the continued functionality and safety of military systems.

Aerospace Applications of Infrared Coatings

Anti-Reflective Coatings for Aircraft Windows

| Application | Function | Benefits |

| Anti-Reflective Coatings | Reduce glare and improve visibility | Enhanced safety for pilots and passengers, improved clarity |

Example: The Boeing 787 Dreamliner utilizes advanced AR coatings on its windows to provide enhanced clarity and reduce glare, ensuring a more comfortable and safe flight experience.

Thermal Control in Spacecraft

Spacecraft are exposed to extreme temperature fluctuations due to their proximity to the sun and the vacuum of space. To maintain optimal operating conditions for sensitive equipment, IR coatings are used in spacecraft thermal control systems. These coatings help regulate the temperature of the spacecraft, protecting it from extreme heat and cold.

Case Study: The European Space Agency’s Solar Orbiter, launched in 2020, uses IR coatings to protect its instruments and solar panels from the intense heat as it approaches the Sun, ensuring accurate data collection.

Optical Coatings for Satellite Sensors and Imaging Systems

Satellites rely on IR coatings for sensor optimization, enabling them to capture high-quality infrared images of the Earth and beyond. These coatings enhance sensor sensitivity and reduce reflection, improving the clarity of images captured by satellites, which is crucial for weather monitoring, reconnaissance, and space exploration.

Example: NASA’s Hubble Space Telescope uses specialized IR coatings to maximize light capture, reducing reflections and ensuring the clarity of images of distant galaxies and celestial phenomena.

Advancements in Infrared Coating Technology

Nano-Structured and Multi-Layer Coatings

Advances in coating technologies have led to the development of nano-structured and multi-layer IR coatings. These coatings provide better control over infrared light transmission and reflection, enabling more efficient thermal management and optical performance. In military and aerospace applications, multi-layer coatings are used to optimize performance under varying environmental conditions.

Future Trends in IR Coating Materials

As the demand for more durable and energy-efficient materials grows, the future of infrared coatings looks promising. Innovations in material science are expected to lead to coatings that offer better thermal resistance, longer-lasting durability, and improved performance under extreme environmental conditions. These advancements will play a critical role in ensuring the longevity and reliability of military and aerospace equipment.

Key Challenges and Solutions in Military and Aerospace Sectors

Environmental and Operational Factors

One of the key challenges in using IR coatings in military and aerospace sectors is their performance under extreme environmental conditions. The coatings must be able to withstand high temperatures, UV exposure, and mechanical stress. Advances in coating technology are addressing these challenges by developing materials that offer better durability and resistance to harsh conditions.

Cost and Manufacturing Considerations

| Manufacturing Consideration | Challenge | Potential Solutions |

| Material Costs | High cost of advanced materials | Research into more affordable materials and production methods |

| Production Efficiency | High complexity in manufacturing | Streamlining production processes to reduce costs and time |

The cost of manufacturing advanced IR coatings can be high, especially when using specialized materials and techniques. Balancing performance with cost-effectiveness is crucial, particularly when scaling up for large military operations or aerospace projects. Efforts to optimize production methods and reduce material costs will help make IR coatings more affordable and accessible.

Conclusion

Infrared coatings are crucial in military and aerospace sectors, enhancing thermal management, stealth technology, and sensor performance. These coatings are vital for systems such as night vision and spacecraft thermal control, ensuring the durability and safety of sensitive equipment.

The advancement of IR coating technology will continue to drive progress in defense and space exploration. As the need for more efficient and durable coatings increases, industries will increasingly rely on innovative solutions like those from TAIYU OPTICAL GLASS. Their products, known for superior quality and reliability, play a key role in meeting the evolving demands of these critical sectors.

FAQ

Q: What are infrared optical coatings and how do they work?

A: Infrared optical coatings are thin layers applied to materials to control the reflection or transmission of infrared light. These coatings enhance the performance of optical systems by either blocking or allowing specific infrared wavelengths, depending on the application.

Q: How are infrared coatings used in military applications?

A: In the military, infrared coatings are used in thermal imaging systems, night vision goggles, and stealth technology. They help reduce heat signatures, improve detection capabilities, and provide protection against laser threats.

Q: Why are optical coatings important in aerospace?

A: Optical coatings, including infrared coatings, are vital in aerospace for thermal control, reducing glare, and enhancing sensor performance. They ensure spacecraft and aircraft systems perform optimally in extreme conditions.

Q: What are the advantages of using infrared coatings in spacecraft?

A: Infrared coatings help regulate temperature, protecting sensitive instruments from extreme heat and cold. They also enhance the clarity of satellite sensors, ensuring accurate data collection in space exploration.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori