Introduction

In today’s digital age, optical coatings—especially anti-reflective (AR) coatings—have become vital components in the world of consumer electronics. As devices become increasingly integrated into our daily routines, consumers expect better screen visibility, improved performance under various lighting conditions, and enhanced durability. This shift has created a significant surge in demand for high-quality anti-reflective optical coatings across smartphones, tablets, wearable devices, and flat-panel displays.

Anti-reflective optical coatings are thin-film layers applied to surfaces such as glass or plastic to minimize reflection and glare while enhancing light transmission. These coatings enable better screen readability in bright environments and contribute to energy efficiency by reducing backlight requirements. In an era where aesthetics and performance go hand-in-hand, AR coatings play a crucial role in meeting consumer expectations and industry standards. As a result, the optical coatings market—especially in the context of consumer electronics—is experiencing robust growth and innovation.

What Are Anti-Reflective Optical Coatings?

Function and Composition

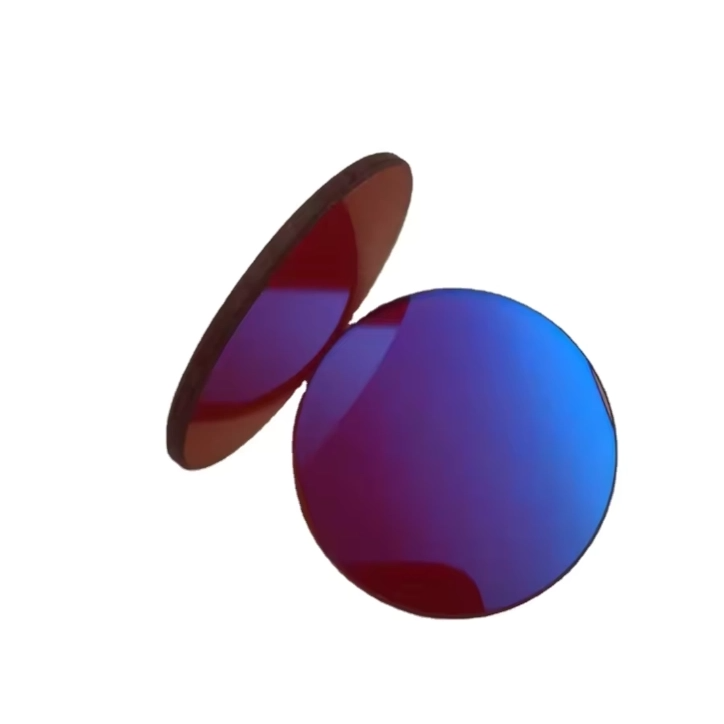

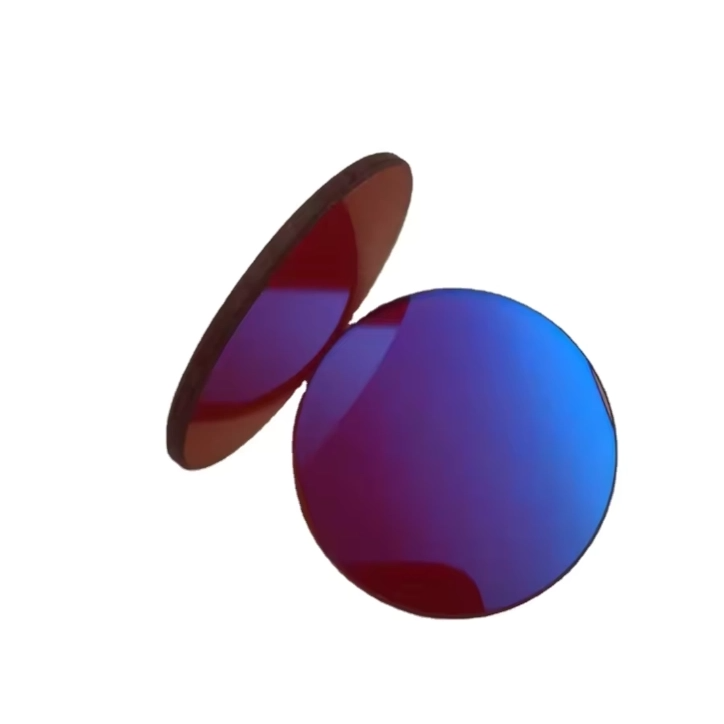

Anti-reflective optical coatings are engineered to reduce surface reflection by interfering destructively with incident light. They typically consist of multiple thin layers of dielectric materials, each designed with precise thickness and refractive index to achieve optimal light transmission. When applied correctly, these coatings can reduce reflectance to less than 1%, making screens appear clearer and sharper.

The materials used in AR coatings range from magnesium fluoride (MgF₂) to more advanced multi-layer structures involving titanium dioxide (TiO₂) and silicon dioxide (SiO₂). The application techniques include physical vapor deposition (PVD), chemical vapor deposition (CVD), and ion-assisted deposition (IAD), depending on the complexity and required durability of the final product. These coatings are particularly effective across visible wavelengths and are tailored for both front and back surfaces of display components.

Market Drivers for AR Coatings in Consumer Electronics

The Surge of Mobile and Wearable Devices

The proliferation of mobile devices has drastically reshaped the consumer electronics landscape. Smartphones alone are expected to reach over 7 billion users globally by 2025. With this explosion comes a higher demand for screens that are not only responsive but also visible in outdoor lighting conditions. Anti-reflective coatings directly address this need by ensuring displays remain legible in bright environments.

Wearable devices such as smartwatches and fitness trackers further emphasize the importance of AR coatings. Due to their smaller screens and frequent outdoor use, wearables require high-performance coatings to maintain functionality and user satisfaction. The increasing emphasis on health monitoring and on-the-go connectivity ensures that the demand for durable, clear, and low-reflection surfaces will only intensify.

Key Challenges in AR Coating Application

Durability and Environmental Resistance

While AR coatings offer impressive performance, one of the main technical challenges lies in ensuring long-term durability. Consumer electronics face exposure to various harsh conditions—scratches, temperature fluctuations, moisture, and even corrosive environments. Coatings must therefore balance anti-reflective properties with mechanical and chemical resilience.

This need has led manufacturers to innovate with hybrid coatings that combine anti-smudge, anti-scratch, and anti-glare functionalities. The inclusion of oleophobic or hydrophobic top layers helps improve user experience by reducing fingerprints and enhancing cleaning ease. However, ensuring these multilayer coatings remain intact over years of use remains a significant hurdle and a key area of ongoing R&D investment.

Regional Trends and Growth Forecasts

Asia-Pacific Leading the Demand Curve

The Asia-Pacific region, particularly China, South Korea, and Japan, dominates the manufacturing and consumption of consumer electronics. As a result, these countries are also at the forefront of optical coating adoption. With local giants in the semiconductor and display panel industries, the regional demand for advanced coatings continues to rise rapidly.

According to recent market forecasts, the global anti-reflective coatings market is projected to surpass USD 6 billion by 2027, with consumer electronics accounting for a substantial portion of this growth. Increasing disposable income, urbanization, and the proliferation of high-end consumer gadgets are driving this trend, especially in developing economies.

Comparative Table: AR Coatings in Common Consumer Electronics

| Device Type | Key AR Coating Benefit | Expected Lifespan | Market Share Growth (2023-2027) |

| Smartphones | Glare reduction, readability | 2–5 years | High |

| Tablets | Eye strain reduction | 3–6 years | Moderate |

| Wearables | Sunlight visibility, scratch resistance | 1–3 years | Very High |

| Laptops/Monitors | Color clarity, energy efficiency | 4–7 years | Steady |

| VR/AR Devices | Immersive display enhancement | 2–4 years | Emerging |

This table underscores the wide-ranging application of anti-reflective coatings and their tailored benefits across device categories. While smartphones and wearables represent high-volume use cases, AR/VR devices are emerging as new frontiers in coating demand.

FAQs – Understanding the Value of AR Coatings

Are AR coatings necessary for all electronic screens?

Not all screens require anti-reflective coatings, but they are essential for any device used in variable lighting conditions or with high visual performance demands. They enhance user comfort, reduce eye strain, and improve visual clarity, making them indispensable for premium electronic devices.

How do AR coatings impact display quality?

By reducing reflection and increasing light transmission, AR coatings enhance contrast, sharpness, and color fidelity. This leads to a more vibrant and immersive visual experience, particularly in brightly lit environments.

Do AR coatings wear off over time?

AR coatings can degrade over time, especially if the surface is subjected to frequent abrasion or chemical exposure. However, high-quality coatings with protective top layers can maintain their effectiveness for several years under normal usage conditions.

Conclusion

As consumer expectations continue to rise, manufacturers are under increasing pressure to deliver visually superior and durable electronic devices. Anti-reflective optical coatings are no longer optional—they are a competitive necessity in the design and engineering of modern electronics. With advancements in deposition technology, material science, and environmental resistance, AR coatings will only grow in importance.

In the coming years, we can expect to see a convergence of AR coatings with other multifunctional layers, resulting in smart surfaces that are not just optically optimized but also self-cleaning, anti-bacterial, and even touch-responsive. For stakeholders across the consumer electronics value chain—from material suppliers to OEMs—the future of optical coatings holds immense promise and transformative potential.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori