Wholesale Eyeglass Lens 1.56/1.60/1.67 Progressive Optical Manufacturer Lenses

Anti-reflection coating is an optical coating with a wide range of applications, widely used in daily life, industry, astronomy, military science, electronics and other fields. With the development of electronic industry and computer, anti-glare anti-static film for display and computer screen protector have become new application fields of anti-reflection film, which can not only effectively improve the conversion efficiency of battery, but also improve the mechanical properties, electrical properties, Optical properties and other physical and chemical properties.

Product Features

Premium Material Selection: The lenses are crafted from superior base materials, ensuring exceptional optical performance and excellent thermal stability. The manufacturing process includes precision techniques such as slicing, polishing, and grinding, which contribute to the lenses' high-quality finish and enhanced functional properties.

High Temperature and Laser Resistance: These lenses are specifically designed to endure high temperatures and exhibit strong resistance to laser damage. This makes them highly reliable for use in demanding applications where heat and laser exposure are frequent, offering superior protection in environments where durability is crucial.

Imported Quartz Crystal: The lenses are made using imported quartz crystal, known for its high mechanical strength. This material ensures that the lenses are resistant to both high temperatures and high pressure, which makes them more durable and less prone to cracking under extreme conditions. This feature is particularly valuable in industrial applications where the lens is subjected to intense physical stress.

Anti-Reflection Coating: The lenses are treated with a high-damage-threshold anti-reflection coating on both sides. This coating reduces unwanted reflections, improving the clarity and quality of the transmitted light. In addition to enhancing optical performance, the coating also serves as a protective barrier against splashes, dust, and other potential contaminants, ensuring the longevity of the lens and maintaining its high functionality.

Enhanced Durability and Long Lifespan: With a focus on resilience, the lenses are engineered to maintain their integrity under harsh environmental conditions. They offer consistent performance even when exposed to mechanical stress, high temperatures, and pressure fluctuations. This exceptional durability extends the lifespan of the lenses, making them a reliable choice for both commercial and industrial uses.

Increased Safety Features: The combination of high-quality material selection, precise manufacturing processes, and protective coatings ensures that the lenses are not only efficient but also safe for prolonged use. They are designed to withstand impacts, abrasions, and extreme temperatures, minimizing the risk of damage and enhancing overall user safety.

Versatile Application Range: These lenses are suitable for a wide range of applications, from high-precision optical systems to high-powered laser equipment, where both clarity and durability are critical. The strength and resistance properties of these lenses make them ideal for use in industries such as telecommunications, medical technology, and scientific research.

Product Advantages

Fast and Reliable Delivery: Enjoy the convenience of quick delivery for high-quality 1.56 blue cut optical lenses with our wholesale pricing, perfect for businesses and individuals seeking efficient shopping experiences.

Advanced HMC Coating Technology: Our lenses are coated with high-quality HMC (hydrophobic and oleophobic coating) to reduce glare and smudges, providing users with clear and sharp vision.

Customizable Options: We offer sample creation and mold-making services, allowing customers to create lenses tailored to their specific needs and preferences.

Premium Resin Material: Our lenses are made from durable, shatter-resistant resin material, ensuring long-lasting reliability and performance.

Competitive Pricing: Our wholesale pricing makes our lenses an attractive choice for businesses and individuals seeking affordable, high-quality optical lenses.

Product Operate Guide

Progressive Optical Manufacturer Lenses offer a seamless transition between multiple vision zones, catering to near, intermediate, and distance vision without the lines of traditional bifocals. These lenses are custom-made, ensuring a personalized fit for wearers. Advanced manufacturing techniques provide a wider field of vision and reduced distortion. Ideal for individuals with presbyopia, these lenses allow for a natural viewing experience when shifting focus across different distances. As leaders in innovation, progressive lens manufacturers continuously improve lens design for comfort and visual clarity, making them a top choice for a modern, active lifestyle.

Materials and Coatings

The page references both imported quartz crystal and premium resin material, which suggests a portfolio approach rather than a single-substrate lens. In B2B terms, that flexibility matters: resin options support lightweight, cost-effective designs where impact resistance and ease of scaling are valuable, while quartz-class materials are commonly chosen when thermal stability and mechanical strength are non-negotiable.

Coatings are where the lens becomes “production-friendly.” The current page highlights anti-reflection coating on both sides to reduce unwanted reflections and raise the clarity of transmitted light. It also describes coatings as a protective barrier against contaminants such as dust and splashes, supporting longer service life and steadier performance after handling. The mention of HMC (hydrophobic and oleophobic coating) points to anti-smudge behavior—useful when lenses are touched during assembly, cleaned repeatedly, or used in end-products where fingerprints and haze quickly degrade user experience.

Manufacturing, Quality Control, and Consistency

In optics, quality is not one number—it’s a chain. The page references core processes including slicing, polishing, and grinding, which are the backbone of shape accuracy and surface finish. In practical terms, this is how you protect your downstream operations: better surfaces reduce scatter; better geometry reduces alignment rework; better consistency reduces test failures that are hard to root-cause.

To support B2B procurement, your lens program should be specified with a manufacturing-ready mindset:

Process repeatability: aim for stable outcomes across batches so your acceptance tests don’t need constant adjustment.

Handling resilience: the page emphasizes durability under mechanical stress, high temperatures, and pressure fluctuations—important for assembly lines and field reliability.

System-level verification: ensure your incoming inspection matches your optical risk (for example: image contrast checks for imaging lenses, transmission/reflectance checks for coated parts, and stability checks under thermal load where relevant).

When these controls are aligned, buyers see the benefit where it counts: faster assembly, fewer line stops, and fewer surprises in customer feedback.

Customization and Engineering Support

Many lens projects fail at the interface—not because the optics are impossible, but because the part doesn’t truly fit the system. The current page notes sample creation and mold-making services, which are especially relevant for OEMs that must match legacy housings, tight clearances, or a fixed optical path length.

A practical customization workflow for B2B projects typically includes:

Define the optical target: what must improve (contrast, glare reduction, stability under heat, etc.).

Define the mechanical constraints: outer diameter, thickness envelope, mounting surfaces, and cleaning method.

Prototype with intent: short-run samples that validate performance before committing to volume tooling.

Lock the specification for scale: confirm coatings, substrate, and acceptance criteria so procurement and QC are aligned.

This reduces redesign cycles, speeds up qualification, and makes your supply chain predictable—exactly what production teams need when programs move from R&D to volume.

Why Choose Us

Outcome-driven lens engineering: the current page positions AR coating and durability features to solve real performance blockers—glare, contamination, and stability under tough conditions.

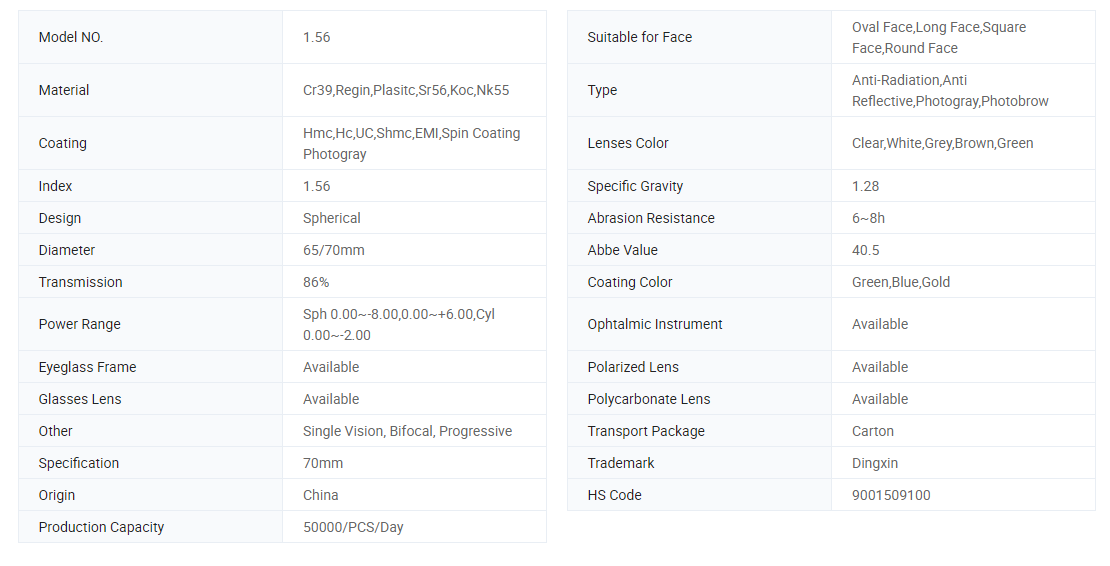

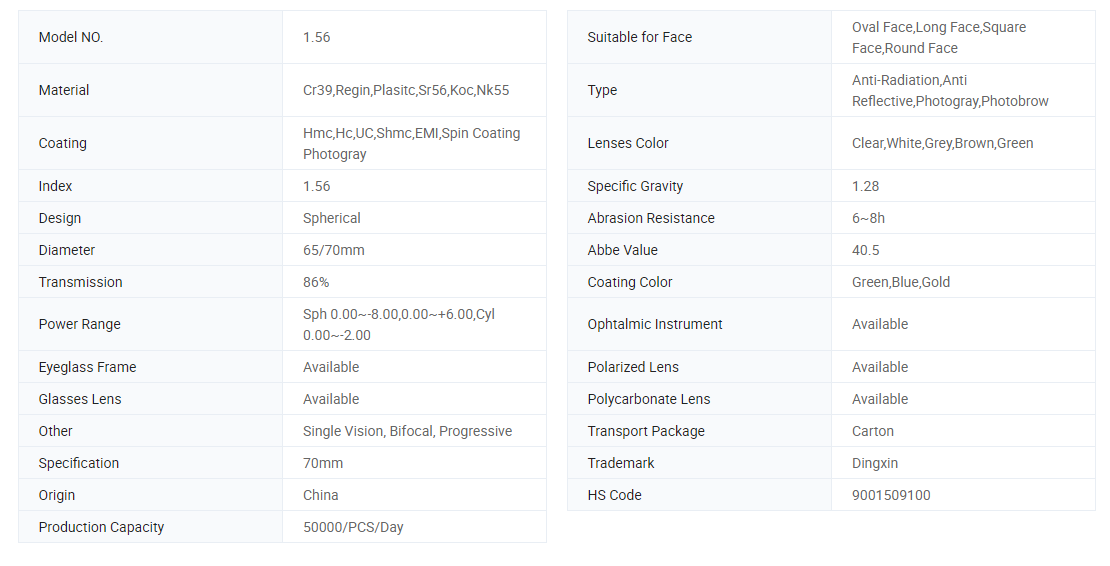

Portfolio flexibility: referenced options include progressive lenses with 1.56/1.60/1.67 indices, plus material mentions spanning resin and imported quartz crystal, giving OEMs room to balance performance and cost.

Customization capability: sample creation and mold-making support helps shorten development time and reduce fitment risk.

Production mindset: the referenced manufacturing processes (slicing, polishing, grinding) reflect a foundation built for repeatable quality rather than one-off prototypes.

B2B commercial readiness: the page highlights competitive wholesale pricing and fast delivery, supporting pilot programs and sustained purchasing plans.

FAQ

1) What information should I provide to quote the right lens?

Start with the application and what failure looks like in your system: glare, distortion, thermal drift, laser exposure, or user smudges. Then share the mechanical envelope and any constraints on thickness, diameter, or mounting. If you already have a reference part, that accelerates the path to a fit-accurate sample.

2) Are these lenses only for eyeglasses?

No. While the current page references progressive optical manufacturer lenses and refractive index options (1.56/1.60/1.67), it also describes high temperature and laser resistance and highlights use cases across industrial, telecom, medical, and scientific fields. That points to a broader lens capability aimed at multiple optical systems.

3) What is the benefit of anti-reflection coating in a B2B system?

AR coating reduces unwanted reflections that can wash out contrast, introduce ghosting, and lower throughput. In inspection and imaging, that can translate into fewer false rejects and more stable measurement results. In user-facing optics, it typically improves perceived clarity and reduces distracting glare.

4) What is HMC coating and when does it matter?

The page describes HMC as hydrophobic and oleophobic—helpful when smudges, fingerprints, and repeated cleaning can degrade clarity. If your assembly process involves frequent handling or your end product is used in touch-prone environments, this coating concept supports a cleaner optical surface over time.

5) Can you support prototypes before mass production?

Yes. The current page notes sample creation and mold-making services. A typical path is sample validation first, followed by final specification lock and scaled production once performance and fit are confirmed.

6) How do I ensure long-term consistency across batches?

Define acceptance criteria that match your risk (optical performance checks, coating behavior checks, and stability checks where relevant), and keep the specification consistent when moving from sampling to volume. If you align incoming inspection with the actual optical function, batch-to-batch variation becomes easier to detect and control.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori